Precision Mechanical Design & Off-Site Manufacturing: Build Smarter.

The core complexity in commercial construction lies in mechanical systems. Our dedicated Design-Build and Manufacturing Services solve this challenge by integrating engineering accuracy with fabrication efficiency, guaranteeing superior quality, predictable schedules, and total cost control for your HVAC and plumbing projects.

We don't just install; we architect and manufacture the future of your facility.

We merge the traditionally separate steps of design and construction into one cohesive, responsible workflow. This integration is managed entirely by our in-house engineering team.

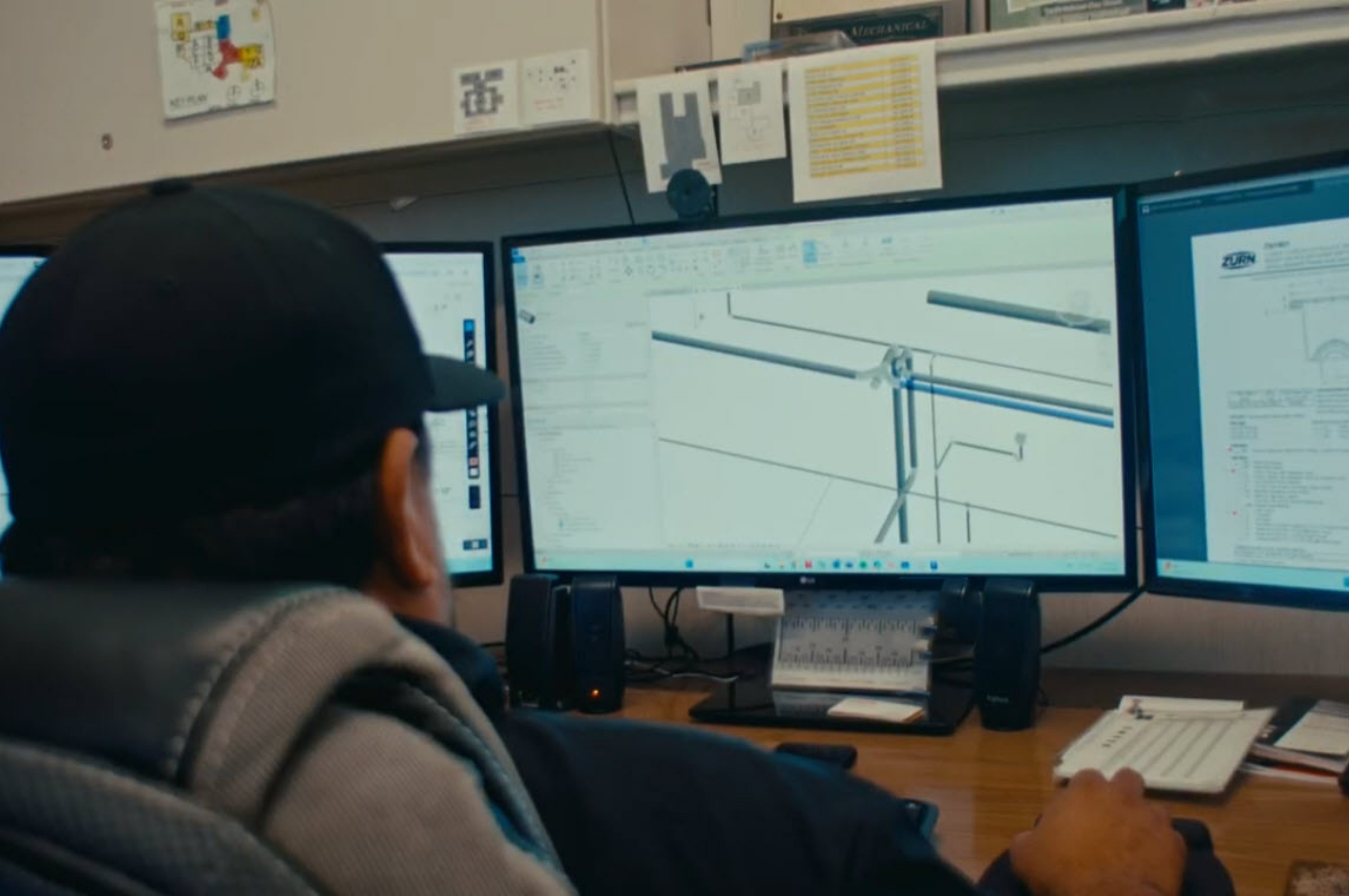

Unified BIM Modeling:

Our engineers utilize state-of-the-art Building Information Modeling (BIM) to create a single, unified 3D model for all HVAC, piping, and plumbing systems. This proactive approach eliminates guesswork and ensures seamless coordination.

Zero Clash Detection:

We resolve spatial conflicts, structural interference, and coordination issues virtually in the model—long before materials arrive on site. This prevents expensive, time-consuming re-work and schedule overruns in the field.

Advanced Value Engineering:

From the initial blueprint, our team analyzes material use, routing, and system sizing to optimize performance, reduce construction waste, and decrease your building's long-term operational costs.

Guaranteed Code Compliance:

Our certified in-house engineers ensure all designs meet rigorous local, national, and specialty commercial codes, streamlining the permitting and inspection process.

Precision Manufacturing & Prefabrication

We shift complex, labor-intensive tasks from the crowded, unpredictable job site into our controlled manufacturing environment. This is where engineered accuracy meets production efficiency.

Factory-Built Quality

All components—from pre-assembled pipe spooling and vertical risers to ductwork and utility racks—are manufactured in-house. This controlled setting guarantees consistent quality, superior welding, and precise fit every time.

Accelerated Installation

By delivering finished assemblies to the job site, we reduce installation time by up to [Insert Percentage, e.g., 30%]. Your installation crews spend less time cutting and assembling, and more time placing and connecting.

Enhanced Safety and Waste Reduction

Moving fabrication off-site dramatically reduces safety hazards and on-site material waste. This translates directly to a cleaner, safer, and more organized job environment for everyone.

Why Choose Our Integrated Approach?

Our Design and Manufacturing services deliver maximum value where it matters most:

| Benefit | Impact on Your Project |

|---|---|

| Schedule Certainty | Eliminate delays caused by field clashes and material sourcing with precision prefabrication. |

| Quality Control | Factory standards guarantee consistent welds, perfect connections, and adherence to exact specifications. |

| Total Cost Predictability | Finalized design models and fixed manufacturing costs mean fewer change orders and no surprise expenses. |

| Reduced Site Traffice | Less material and fewer trades on site lead to a smoother, faster overall construction process. |